SHARE ON:

Link copied!

Non-Torque Loads

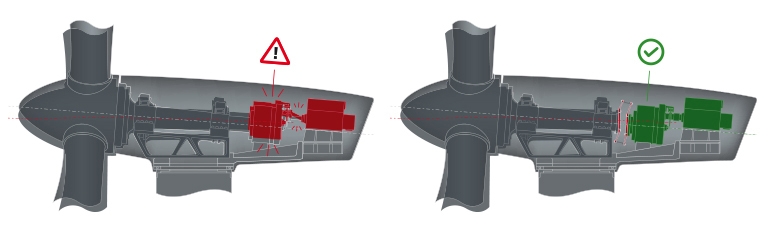

Avoiding parasitic loads by mounting the gearbox rigidly to the main frame and decoupling the rotor from the gearbox is a potential alternative. Geislinger Compowind® is a lightweight, fatigue resistant and maintenance-free low speed shaft coupling made of advanced composites, relieving the gearbox from unnecessary stress and fatigue (figure 1). The latest 8 MW and offshore wind turbines, featuring high integrated drivetrain designs with a low speed shaft coupling between the rotor and the gearbox, confirm this trend.

Dynamic Load Study

The renowned Center for Wind Power Drives (CWD), RWTH University of Aachen, has done comprehensive dynamic load studies on behalf of Geislinger. They clearly demonstrated that Compowind® prevents constraining forces in a rigid bearing arrangement; an abstract hereinafter illustrates the magnitude of load reduction and the potential to enhance the dynamic system behaviour:

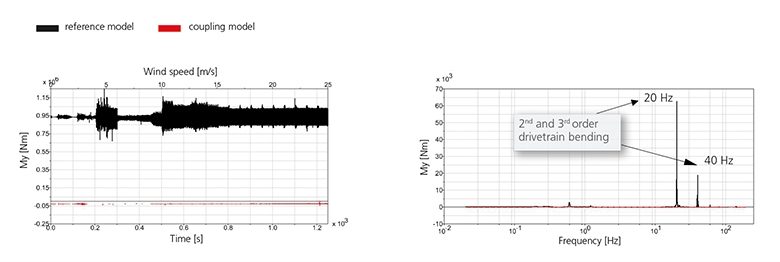

Figure 2: The load comparison of pitching moment (My) at design load shows distinctive reduction of moments and fatigue load (red graph). Figure 3: A modal analysis unveils severe drivetrain modes caused by elastic gearbox mounts (black graph), explaining dynamics and fatigue load in figure 2 (black graph).

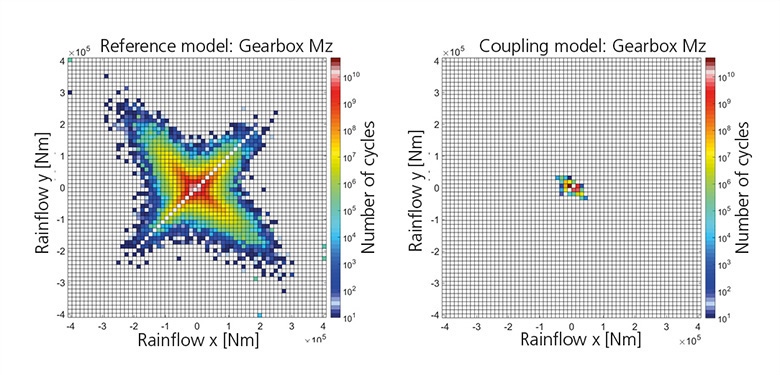

Figure 4: The comparison of yaw moments (Mz) in the Rainflow-counting analysis clearly shows a high number of oscillating cycles and high amplitudes in the reference model which is caused by alternating loads (left). This dynamic effect does not occur in the coupling model thanks to the rigidly mounted gearbox (right).

Commercial Study

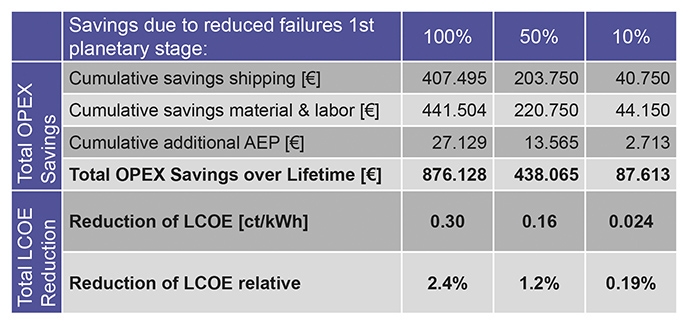

The objective of the study carried out by CWD was to identify the potential of reducing the operational cost (OPEX) of a 6 MW offshore wind turbine under the assumption that Compowind® has the potential to reduce non-torque loads applied to the gearbox input shaft and thus may have positive effects on OPEX as gearbox failures are reduced and the number of gearbox exchanges is decreased. Reduced gearbox failures lead to higher availability of the turbine and therefore the annual energy production (AEP) increases. According to a GE publication in 2016, 61% of gearbox replacements are due to failure within the planetary stage, thereof 36% planet bearings and 25% planetary stage gear (figure 6). Together with an assumed failure reduction of 90%, a realistic best-case reduction potential of a gearbox exchange results in 55%.

OPEX (shipping, material, labour) and AEP values were calculated under the following assumptions (figure 7): 4.500 full load hours annual energy production, 271 GWh over its lifetime, an offshore LCOE reference value of 12.8 ct/kWh, a day rate for a jack-up vessel at 80 k€, average cost for a gearbox exchange at 80 k€, and a number of major replacement at 0.154 annually. The LCOE is calculated by the net value of energy generation over the entire lifetime of a wind turbine (figure 7).

Taking into account that a gearbox replacement at difficult and rarely accessed offshore locations might take much longer than six days, the potential savings will be significantly higher compared to the results illustrated above.